Best Glue For Metal To Plastic : Check Our Top 7 Picks Now!

Whether it’s a DIY project or a simple household fix, we use glues almost on a daily basis. However, not all types of glues are made to be all-purpose. Truth is, there are so many types of glues that serve a particular range of needs.

When it comes to households, we often come across the question that what is the best glue for metal to plastic?

While there’s no short answer to this, there are several types of glue that get the job done. Again, not all plastics are the same. Some are soft whereas some are hard. Sometimes there are specific glues for specific types of metals.

So, what is the ideal glue for your need? And what should you consider before buying one? Let's find out.

Image | Name | Editor's Rating | Price |

|---|---|---|---|

Rhino Glue Gel | 5 out of 5 | ||

Gorilla 2 Part Epoxy | 5 out of 5 | ||

CECCORP Cyanoacrylate Super Glue | 4.5 out of 5 | ||

J-B Weld 8281 Reinforced Epoxy | 4 out of 5 | ||

Loctite Professional Liquid Super Glue | 4.5 out of 5 |

Table of Contents

Types Of Adhesive for Bonding Plastic to Metal

As we have already mentioned, there are different types of plastic and metals. Each of them is purpose-designed to serve specific needs. Some might be food grade; others might be used in home utensils or kitchen wares.

The same holds for metals as well. Based on all these different types of components and use cases, the type of glues differs too.

So, you might be thinking what are the right options for metal to plastic? Below are the factors you need to consider to find the answer.

Epoxy

Epoxy is an all-around winner when it comes to the strongest glue for plastic to metal. This is more like an all-purpose solution for all types of plastic and metals.

The main feature of epoxy is the high strength and high-intensity bond that is created between the components.

And the best thing is that they are water and weather-resistant. So, you can be sure that this bond will last you a lifetime.

There are two components of an epoxy bond – one is a hardener and the other is the epoxy itself. A strong bond is created when the two components are mixed in a specific ratio.

The key here is the ratio. Whether the bond will last a long time or not depends on the ratio you are using and the amount to be used. You need to be careful about this when you make the mixture.

Cyanoacrylates

We know the word is a mouthful. But that’s just a fancy way of saying it’s an all-purpose super glue. We are all familiar with super glues, they are something that we use regularly. Super glues can be a good choice to bond hard plastic and metal.

However, super glues aren’t exactly the ideal bonding solution for a smooth surface. So if your metal or plastic has a smooth surface, you can either roughen them up a bit or choose a different solution.

Silicone Adhesive

Are you worried about extreme temperatures? Often, we see the use of plastic and metal bonds for outdoor needs. The heat from the sun might get extreme at times and it will ultimately deteriorate the bond. That is unless you use a silicone adhesive.

The key feature of silicone adhesive is that it can withstand extreme temperatures. Also if you are working with soft plastic, silicone adhesive should be your go-to choice.

However, you do need to keep in mind that, unlike epoxy and superglues, silicone doesn’t harden up instantly. Rather it might take up to a few days to be fully curated.

Hot Glue Gun

You might be thinking, is your kid’s hot glue gun for DIY projects good enough to bond metal to plastic?

Truth is, they’re not. There's a difference between a craft-grade glue gun and an industrial glue gun.

And you’ll be needing the latter. There is a wide variety to choose from. There’s EVA, polyamide, or acrylic. You just need to check which one is suitable for your particular job.

Polyurethane Adhesives

PU adhesives are a good choice for all sorts of plastic and metal bonds. If you are looking for a waterproof adhesive for metal to plastic, this one can be a great choice. They bond well on soft plastic too. You just need to make sure they’ve hardened properly.

UV Cure Adhesives

If you want something fancier for your bond, then definitely check out UV cure adhesives. These adhesives are slated for all-purpose use on different materials.

However, the only constraint is that they require UV radiation to cure. Once the UV ray curing is properly done, rest assured that the bond will do its job.

Our 7 Best Glue For Metal To Plastic 2023

1. Rhino 40 Gram Glue Gel

The Rhino Glue gel is a premium product from the Rhino Glue line. The company specializes in adhesives for all types of components and materials. This 40 ml gel can be a great bonding solution for all types of plastic to metal bonding.

It comes as part of a long line of glues produced by the company. The gel is a thicker version of their famous rhino glue.

It uses the Rhine Epoxy formula, which makes it the strongest glue for metal to plastic bonding. You will get instant curated bonding with this one compared to the standard glue.

The company has updated the formula for the glue to be better weather and impact resistant. So, if your plastic and metal fusion bumps around places, you can be assured that it won’t affect the bond.

The amount is perfect for multiple uses. There is a common issue of glue hardening within the bottle. However, there are no such issues with this gel formula. You can sure to get your money’s worth out of this one.

Highlighted Features:

- Newer improved formula.

- Instant bonding capability.

- Designed for several different surfaces.

- Impact and shock-resistant.

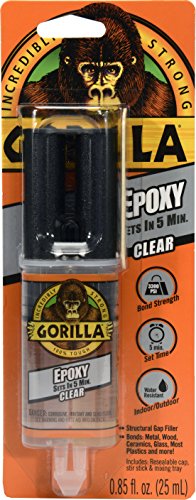

2. Gorilla 2 Part Epoxy for Metal to Plastic

If a company has made its name for all the right reasons, it has to be Gorilla. Their instant bonding solution took the market by storm and it's easy to understand why.

The Gorilla 2 part epoxy is hands down the best glue for metal to plastic bonding. Let's have a look at why they are so loved by the customers.

The epoxy comes in easy-to-use two-part syringes. This makes it easy to mix and assemble, taking away the hassle of manual mixing.

You are getting a 5 minute set time with this one. Generally, epoxies are designed to be instant bonders, making them impossible to reposition once the glue is applied.

The Gorilla 2 part comes out of this one-shot dilemma and gives you plenty of time to reset and reposition your bonding.

While most syringe epoxies are one-time use, the added cap for the syringes means you can use the glue multiple times. The clear nature of the glue makes it easy to clean and finish off after applying.

The epoxy element makes the glue perfect for all-weather use and impact-resistant against all sorts of tough terrains.

Highlighted Features:

- Longer setting time.

- Easy to use two syringe design.

- Tough and durable solution.

- Can be used multiple times.

3. CECCORP Cyanoacrylate Super Glue

CECCORP is another well-known brand when it comes to adhesives. The company has been making bonding solutions for different materials for quite a few years now.

Their cyanoacrylate super glue can be a great adhesive for metal to plastic bonding. The special feature of this glue is its nozzle. The problem with many mainstream types of glue out in the market is that the nozzle gets clogged and eventually hardens.

This makes it impossible to use the glue multiple times. Thankfully, this super glue comes with an anti-clogging mechanism for the nozzle.

The glues also have an amazing consistency. This makes it easy to spread across any surface evenly. However, you need to keep the glue at a controlled temperature of 10°C to 25°C.

Since this is a cyanoacrylate element, this glue gets bonded almost instantly. As a result, you have to be careful while placing the material as you might not get a chance to reposition them.

The high viscosity of the glue makes it the best glue for plastic and metal surfaces. And if you’re concerned about water damages, rest assured as the glue is completely waterproof.

Highlighted Features:

- Instant bonding capabilities.

- High viscosity combined with amazing consistency.

- One glue for all types of surfaces.

- Anti-clogging mechanism.

4. J-B Weld 8281 Professional Reinforced Epoxy for Metal to Plastic

J-B Weld is a well-known brand for all types of home renovation supplies. The company has made its name by making some of the finest welding equipment out in the market. Their reinforced epoxy is one of the strongest metals to plastic glues that you can find.

The glue is made as a commercial-grade adhesive for industrial use. However, the ease of design and handling makes it a perfect choice for amateur home uses as well.

The total volume of the epoxy glue comes at around 147 ml. The tight sealant cap makes it easy to use and reuse whenever necessary.

The problem with epoxy glue is the measurement for the mixture. Many people tend to get the concentration wrong while mixing, which renders the mixture useless. However, the J-B weld epoxy is made to be mixed at a 1:1 ratio which is much easier to keep track of while mixing.

The epoxy glue is a high-density one with a tensile strength of up to 5020 PSI and heat resistance of up to 287 degrees Celsius. And to top things off, the epoxy is completely waterproof, petroleum and chemical proof as well.

Highlighted Features:

- High tensile strength and heat resistance.

- 6 hours of setting time.

- Completely sanding, dusting, molding, and drillable.

- DIY design kit.

5. Loctite Professional Liquid Super Glue

Epoxies are a great choice to bond metal and plastics. However, they take a ridiculously long time to set. If you want something that sets instantly, then super glues are your ideal option.

As the name suggests, the superglue is made as a professional-grade bonding solution. As a result, you can expect industrial-grade quality and adhesion from the glue. Since it’s superglue, the setting time is incredibly fast. In addition to that Loctite used a fast-setting formula on this one.

Another smart feature of the glue is that it dries clear. Meaning you won’t have to worry about it leaving any mark. Your bond will look just as you want it to, minus the trouble of hiding the bond.

The glue for metal and plastic is made to withstand extreme heat and moisture, something that doesn’t always come as a standard with commercial-grade super glues. Whether it's heavy-duty needs or a simple home repair, the Loctite super glue will have your back.

Highlighted Features:

- Transparent when dried off.

- High resistance to extreme heat and moisture.

- Super strength formula.

- Professional grade bonding.

- Pinpoint nozzle for precise application

6. Gorilla All-Purpose Epoxy Putty Stick

If liquid glues and epoxies aren’t your jam, you can always check out the all-purpose epoxy putty by Gorilla. We have already talked about Gorilla; how incredibly popular they are with their products. And the putty is no less when it comes to bonding metal to plastic.

Epoxy putties high tensile strength. As a result, they are used in commercial-grade projects. The Gorilla all-purpose putty can withstand up to 1550 PSI of pressure which makes it incredibly durable for any kind of use.

The setting time for the putty is 10 minutes. Hence, you’ll get ample time to set your bond properly. The putty dries grey. This might be an issue for anyone looking for clear dry bonding.

You can drill, sand, and paint the bond after it completely dries. It's waterproof, so you can stay completely worry-free if your bond is out in the open. However, the putty isn’t rated for underwater uses.

Overall, if you are looking for something that’s not directly glue-based, the gorilla putty can be a great choice for you. As for metal to plastic uses, it will work with all plastics except polypropylene and polyethylene.

Highlighted Features:

- A great alternative to traditional glue

- Higher setting time

- Perfect for outdoor use

- Can be sanded, painted, and drilled

- Not suitable for underwater uses

7. J-B Weld 8272 Marine Epoxy

One of the common queries with epoxy bonding is whether they are good for underwater usage. While many brands claim that their products are rated to be completely waterproof. The durability of the bond gets significantly low if it's submerged underwater.

The J-B Weld 8272 MarineWeld can be a great choice in this regard. As the name suggests, this epoxy- bond is made for marine purposes.

The company exclusively brands the product as your all-in-one solution for any bond dealing with water. Whether it’s a watercraft or a wooden bank, this epoxy works great making it the best epoxy for plastic to metal in waterbodies.

Just like other J-B Weld products, the epoxy for metal to plastic bond comes in a 1:1 ratio making it easier to mix and set. the setting time is a whopping 6 hours meaning you can make changes as many times as you want within that timeframe. The duration time is 16 to 24 hours, so it's better if you leave it to bond at a secluded place.

If you are looking for something that will dry clear, this one’s not for you. The Marineweld takes a dark grey color after drying. The compound is safe for sanding, drilling, and painting.

The bond is slated to withhold up to 5020 PSI and 287 degrees Celsius of temperature. It’s also resistant to acid, petroleum and chemicals. The marine weld can be a good choice if you are looking to bond aluminum to wood or plastic, fiberglass or other metals.

Highlighted Features:

- High set and cure time

- Perfect for water contact bonding

- Fully chemical and acid-proof

- Designed for all sorts of plain and rough surfaces

Comparison Chart of Glue for Plastic and Metal

Brand | Tensile Strength | Setting time | Waterproof |

|---|---|---|---|

Rhino | Medium | Instantly | Yes |

Gorilla | -- | 10-12 hours | Yes |

CECCORP | Medium | Instantly | Yes |

J-B Weld | High | 16-24 hours | Yes and submergible |

Loctite | Medium | Instantly | Yes |

Gorilla | High | 10-12 hours | Yes, but not submergible. |

J-B Weld 8272 | High | 16-24 hours | Yes, and submergible |

Glue For Metal To Plastic : What to Look Before Buying?

Now let's look at the buying factors crucial to get the best glue for metal to plastic bonding, so that you can make an informed purchase decision.

Choosing the Right Glue

We have mentioned above the different types of glues that are great choices for metal to plastic bonding. While all of them are perfect for the bond itself, the different types serve different specific purposes.

If you want a clear bond, it's better if you go for polyurethane or cyanoacrylate glues. If you want something with high tensile strength, you should go for epoxy-based glues.

Understand The Hazards

The polyurethane and cyanoacrylate glues are chemically hazardous compounds. They can cause irritation and burns when coming in contact with the skin. There are countless examples of finger joining while mishandling super glues.

So it's important to take note of the health hazard associated with each of the glue types before making the purchase. Also, you should wear proper safety gear (hand gloves, goggles) when handling them.

Understand The Measurements

Bonding glues come in all types of shapes, sizes and contents. If you are getting yourself glues for DIY project, there is no need to buy a high volume one.

For epoxies, the mixture measurement of the epoxy and the hardener plays a crucial role in bond formation. A wrong ratio will render your bond useless.

The same goes for the set and curation time of epoxy and other types of glues. These are the aspects that you should take care of while making the purchase.

Paying Attention To The Colors

It's important to note the color component of the glues. More often than not, people look for clear glues and end up buying glues that curates to dark grey or grey color. This often completely distorts the look of the bond. So before purchasing the glue, make sure you are buying the color grade you need.

Know How To Store

Most of the time we don’t use the entire glue at one go. However, improper storing often makes the remaining glues unusable.

Try purchasing a glue that has proper storing mechanism in place. Make sure that there is no residual air left after the usage. Also, ensure that the nozzle area is properly cleaned so that it doesn’t get jammed up. And always remember to seal the cap tightly!

Be patient

The curation time differs from glue to glue. Some might have 10 hours on their level, or some might take several hours more. Whatever the time frame be, we suggest that you wait at least 24 hours before applying any significant tension to the bond. This will ensure the longevity of the bond as well as proper curation.

How To Attach Metal To Plastic?

We’ve outlined below the key points to consider when attaching metal to plastic-

- Make sure the surface is clean and dry for both metal and plastic.

- Understand the bonding need (strength, drying color, cure time) before buying the adhesive

- Choose the adhesive based on your need.

- Make sure the ratio of the epoxy base is correct.

- Check for the waterproof rating.

- Check for setting time as you might need to reposition.

- Depending on the adhesive you choose, roughen up the surface of the metal or the plastic before applying the adhesive.

- Give the bond ample time to cure and strengthen.

Frequently Asked Questions

1. Is There Any Need For Surface Preparation Before Bonding Metal To Plastic?

Answer: In general, no, there is no particular surface preparation procedure before applying the adhesive. However, you’ll still be required to follow certain basic measures like cleaning and drying the surface before applying the surface.

And if you feel the bond will be on high tension, it's suggested that you should roughen up the surface beforehand.

2. Is Craft Glue Good For Metal To Plastic Bonding?

Answer: Craft glue is designed for porous surfaces. As a result, it's best suited for naturally rough surfaces like paper and wood. So, it’s not ideal for metal to plastic bonding. Epoxy glue for metal to plastic would be a better option.

3. Is Superglue A Good Choice For Metal To Plastic Bonding?

Answer: Yes, super glue can be a good choice for metal to plastic bonding. However, there are other better solutions like epoxy. Epoxy metal to plastic bonds take some time and allows you to reposition the setup if needed.

However, you can definitely use superglue for the purpose. Make sure that you roughen up the surface before applying the adhesive.

4. Should I Buy Waterproof Glues For All-Purpose Use?

Answer: It completely depends on your choice. If you think the bond will be exposed to water bodies or rain, you must buy waterproof adhesive to protect the bond. If it's something that will stay indoors, you can get on without waterproof adhesives.

Final Words

So there you have it folks, our comparative takes on the best glue for metal to plastic bonds.

Truth be told, there are countless types of glues out in the market. but not all of them are designed to be the perfect adhesive for this specific need.

As a result, you need to be extra careful while making the purchase. We have included a buyer’s guide in this article as well to make sure you make the correct purchase. Here’s to you making the perfect bond with perfect adhesives!