Glass Blowing Tools List For Beginners ( Definitive Guide )

Ever caught your eyes on a beautiful glass vase or showpiece and marvel at its elegant design?

One of the major ways the designers achieve such artistic motifs and shapes is glass blowing.

While it may sound like a weird mechanism to many, this is actually among the most popular and interesting methods of glass-forming.

If you grow an interest in glass blowing, you can actually start implementing your ideas after gathering the necessary tools and taking the essential security measures.

In order to help you get started, we are going to go through the glass blowing tools list so that you know what exactly to invest in.

Table of Contents

Glass Blowing Equipment List

Since glass blowing is no small feat, you cannot DIY it in a cozy room. You will need a large studio space to get started with it even in the beginner stages. That is because it has to accommodate huge objects like a furnace, annealers and more.

Besides, make sure it has enough ventilation to keep the room temperature as normal as possible. When you are done with fixing the surrounding environment, start gathering the glass blowing equipment pieces one by one!

1. Furnace

The furnace is undoubtedly the most important thing you will need to get started with glass blowing. Without a furnace, it will be impossible for you to carve out the shape or design you want from your raw materials! That is because they require very high temperatures to melt down well enough for the transformation.

Glass requires around 1600 to 2400 degrees in Fahrenheit for this method to work. Only a furnace can generate such high heat where the glass turns into bright orange or white-hot.

2. Annealer

Annealing means the process of heating up the glass and then letting it cool down gradually for eliminating the internal stresses. In the case of glass blowing, an annealer is used for the cooling part which can last anywhere between hours and days. The period varies according to the size of your pieces.

It is basically a long oven made in a tunnel-like shape. By using an annealer, you can prevent thermal stress from breaking down or cracking the glass. As a result, there is less chance of accidents and production failure. Another name for this equipment is lehr.

3. Blowpipe

You may call this your main weapon in the glass blowing game since a blowpipe is what helps you to manipulate the molten material into your desired shape.

As the name suggests, it is a pipe of remarkable length through which you need to blow the air. It also maintains a safe distance between the hot material and you.

Blowpipes are usually made of metals like brass and iron. They mainly help to make the first step of the glass blowing process successful. Besides, when you hold it horizontally, these pipes are strong enough to carry the heavy molten glass.

4. Punty

Punty or pontil is an essential tool for glass blowing which helps the craftsman to hold the workpiece in place while working on its design.

It is a long metal rod whose tip has some hot glass. After you have shaped the glass vessel according to its requirements, you will need to attach punty to that vessel’s bottom portion. It will hold the vessel as you finish your work on the top area.

Because of its attachment at the bottom, you may often see a ring-like scar under your vases or bottles made of glass.

5. Jacks

These are the bladed tools in the shape of a hairpin or tweezers. Glass blowers use them to cut in the jack line which separates your blowpipe from the vessel. Jacks also help to shape the sidewalls properly so that the vessel has an all-around uniform body.

A jack made for glass bowling comes with two blades having straight edges. The blades can be metal or wooden. The former type is the more common one while the latter is used mostly for shaping bowls. They come in many varieties of sizes and design for versatile use.

If you are a newbie, it may take you quite some time to master the proper use of jacks since balancing the vessel during rotation is quite tricky.

6. Bench

For any kind of glass blowing work, you will need a bench to be the workstation. They are usually made of a steel frame, metal shields and wooden seats.

It will function as your seat, arms rest, storage, safety measure and more. When the glassblower is rotating or rolling the vessel at work, you can rest your arm here to hold the punty. Besides, its metal shields keep your legs safe when you work with the hot raw glass.

7. Block

One of the many glass blowing tools used for shaping the vessel is a block. Even though its name is quite generalized, these blocks usually come in the shape of a spoon. As a result, it becomes easier for you to mold the hot glass into a proper spherical shape.

You may need to use the block for smoothing out the vessel as well. These are important during the initial stages of glassworking.

8. Mold

In order to attain more specific shapes with flawless curves, glassblowers often use molds. Since human creativity is seemingly endless, these molds come in many sizes and materials.

They can be broadly categorized into two groups - single-piece and multi-piece. You can use the first one for producing the finished vessel or object, while the second one deals with joining multiple panels together.

One of the most popular molds for glass blowing is the optic mold made of metal. This is what makes the lines or patterns on your beautiful glass vessel so smooth and fine.

9. Crimp

Contrary to the above-mentioned items, this is not one of the essential tools you will need for a glass blowing session. However, if you are planning to up your game by instilling some decorative elements on the glass vessel exterior, crimps must be in your possession.

These are basically pieces of equipment that create decorative indentations on the freshly finished glass. When the vessel is still quite hot and soft enough to mold, the glassblower subjects it to the crimp for creating the desired motif.

10. Marver

A marver is a tool made of metal which primarily helps you to roll the blowpipe safely and comfortably. The most common materials that the marver is available in include brass, steel and graphite. You will need to attach it to the wooden or metal table that is used for rotating the warm glass.

These should be cleaned on a regular basis in order to avoid costly production faults. Since it directly touches the glass, any dirt particle residing on it can easily get into the main product and ruin the appeal. So if you get one, remember to keep it clean using steel wool and rubbing alcohol.

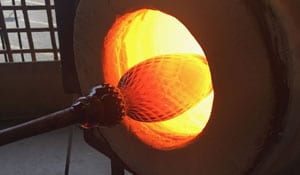

11. Glory Hole

No, it is not some glorious place of mythical creatures or whatever else may come to your mind. The glory hole in glass blowing actually refers to the open front portion of the furnace. Glassblowers use it for reheating a piece with the help of a blowpipe between steps.

It comes in many sizes to accommodate versatile vessels. The oldest glory hole present in the world was built in the UK during the 1850s and is still standing while occupying the space equal to a standard apartment wall!

12. Paddles

Most of us know paddles from rowing boats. However, the paddle used in glass blowing is quite different! Instead of being broad on one or both ends, this paddle is broad for the entire structure except its handle. It is flat all over since paddles are used to flatten the vessel’s base.

13. Yoke

A yoke is one of many support structures that can help you to balance the punty and the blowpipe while rotating it. They can be shaped like a Y or inverse T, often with two wheels at the base. Using a yoke, you can keep turning the vessel without compromising the heat in order to produce a heavier end.

14. Puffer

Puffers or soffiettas look somewhat like arrows, except their sharp ends are conical. These are basically metal tubes with a conical nozzle on one end. Glassblowers use puffers in order to inflate the opening of a finished glass vessel. Usually, these are made of a copper pipe and an aluminum cone.

15. Pyrometer

If you are not familiar with pyrometers, these are simply temperature readers specifically made for extremely high heat conditions.

Their main application is measuring the temperature of furnaces or kilns. So if you are struggling to hit the right temperature in your furnace or to maintain it, use a pyrometer to solve the issue.

16. Shears

Typical cutting tools like scissors and knives don’t work on molten or warm glass. That is why you need to get shears for working with glass blowing. The two types of shears - straight and diamond - which can help you to cut either straight lines or squares into the hot metal surfaces. Make sure their edge is thin before use. You can also use glass cutter for cutting bottles in different shapes.

17. Safety Gear

As you can assume, fragile hot molten glass and a burning furnace do not constitute the safest working conditions. That is why you need to be prepared to prevent common injuries and accidents. The required safety gear for glass blowing includes heat resistant gloves, protective eyewear and closed-toe shoes.

18. Tag

To have even more freedom of implementing creative ideas, you can keep a tag or tagliol for sculpting molten glass. These are special knives with square-shaped ends. Tags usually help with flattening the hot glass surface. However, there are some variations that come with a rounded edge for more versatility.

Conclusion

Although we have discussed 18 different items on our glass blowing tools list, you don’t have to get all of them during the beginner phase. Only get the essentials without which you can’t even practice the basics of this procedure.

When you get familiar with the process, then start investing in the other pieces of equipment which take the creativity to exciting levels!

You can create vases, bowls, bottles and more with glass blowing which can easily help you become an entrepreneur! We wish you the best for all of these inspiring endeavors.

Other Crafting Resource: